- Drymex 污泥干燥系统

- 详细信息

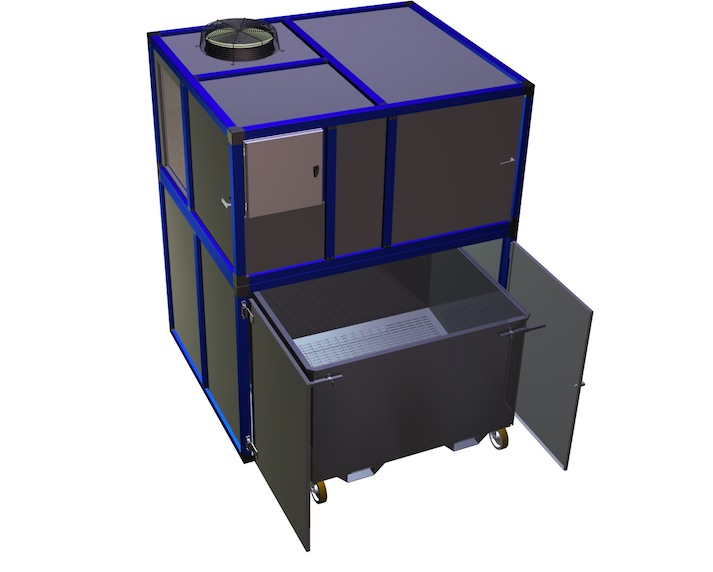

The Harter devised Drymex® sludge drying technology is capable of drying aqueous sludges of any kind in an energy saving, closed system at low temperatures.Such drying decreases the weight and volume of your sludge so that your disposal cost is significantly reduced. Drymex® drying systems are used for previously dewatered sludges.

No matter if you are a plant operator, construction company or planning office – may find advantages of our drying technology, how it works and where it is applied.

Up to 60% Weight Reduction

The use of the HARTER sludge drying systems reducessludge weight and volume by as much as 60 percent.

Example:

Sludge Weight Reduction Obtained by HARTER Drymex®

Up to 60% Disposal Cost Reduction

Weight reduction by as much as 60 percent results in 60 percent disposal cost reduction.

HARTER Pilot Plant Station – To Be on the Safe Side

You can use the HARTER Pilot Plant Station to test the drying characteristics of your sludge before you take the decision to buy a Drymex®.

Almost No Emission

The closed system with heat recuperation uses waste heat which reduces cost of operation and enhances economy – with practically no emission.

Heat Pump System for Low Energy Consumption

Energy consumption varies – with sludge properties and dryer type used – between 0.25 and 0.4 kWh/kg of water.

Lasting Value, Robustness, Reliability

We take an uncompromising attitude towardsselecting top quality material to ensure high availability and lasting value ofour systems. HARTER sludge dryers are corrosion resistant, of lasting value,robust and always reliable.